The Tapes Division designs and produces highly performing adhesive tapes for the most challenging industrial

applications on the global market.

The Tapes Division designs and produces highly performing adhesive tapes for the most challenging industrial

applications on the global market.

A team of highly skilled chemists is continuously working on the development of ranges of performing products with

different degrees of adhesion (removable, repositionable, semi-permanent, permanent and ultra-permanent tapes),

cohesion (Low, Medium and High) and wettability (Wet and Dry).

The high technical expertise of our R&D team, alongside the wide range of supports, liners and adhesives used, enables

BiesSse to provide customized solutions according to the customers’ specific requirements as well as assistance during

the design, development, testing and implementation processes.

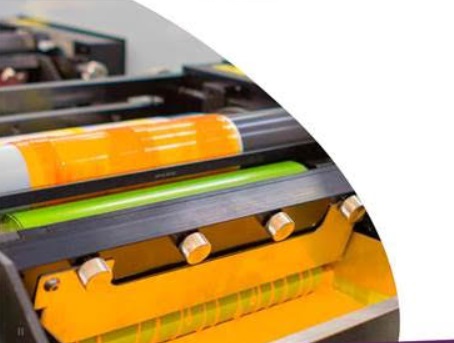

Plate Mounting tapes are as important in Flexo Printing process just as inks are.While the careful selection of the plate

and cylinder are as important for the final print job as the correct selection of the mounting tapes. BiesSse has

evolved a great variety of mounting tapes which can enhance the final print product.

BiesSe cushion mount tapes guarantee easiest plate mounting to cylinders and sleeves, from. The wide foam selection,

you can find differential adhesives, and a wide range of different compressibility foams and thicknesses available.

For haftone work where dot gain are a concern there is a softer version of cushion mount. For solid and dots you

have a range of medium density and for solids and crisp lines a high density cushion tape would give the best results

that customers demand and expect.

The wide range of BiesSse double-sided adhesive tapes, especially

designed for the printing industry, covers all the most important fields of application, such as flexible packaging, labels, pre-print and post-print cardboard.

The wide range of BiesSse double-sided adhesive tapes, especially

designed for the printing industry, covers all the most important fields of application, such as flexible packaging, labels, pre-print and post-print cardboard.

In wide web flexo printing adhesive tapes, used for plate mounting onto the cylinder or sleeve, must offer

high-performance to meet the ever-increasing demands for print quality and efficient production processes.

In wide web flexo printing adhesive tapes, used for plate mounting onto the cylinder or sleeve, must offer

high-performance to meet the ever-increasing demands for print quality and efficient production processes.

The BiesSse range of adhesive tapes covers all printing requirements. The different series of cushion and rigid

doublesided adhesive tapes are differentiated by adhesive performance, thickness and compressibility. They are

characterized by low thickness tolerances, enabling easy mounting and easy removal of trapped air, offer perfect

adhesion during printing, show excellent results even at high speed and long print runs, and allow clean demounting

at the end of the process.

In narrow web flexo printing small diameter cylinders are being used, frequent job changes are made, and different and

complex label designs are the norm. Compared to wide web printing, narrow web printing normally requires adhesive tapes

with higher adhesion.

In narrow web flexo printing small diameter cylinders are being used, frequent job changes are made, and different and

complex label designs are the norm. Compared to wide web printing, narrow web printing normally requires adhesive tapes

with higher adhesion.

Our adhesive tapes provide a perfect plate bonding onto the cylinder or sleeve; they compensate any possible plate

deformation occurring during the print run, and ensure perfect thickness calibration.

View the Product Range

In the flexo pre-printing process the paper reels are

printed before being processed on the corrugator.

In the flexo pre-printing process the paper reels are

printed before being processed on the corrugator.

Large cylinders and high-thickness photopolymer plate are

normally used.

Our adhesive tapes provide very high adhesion levels, solvent resistance and excellent adhesion during the printing process.

In the direct flexo printing of corrugated board,the adhesive tapes must allow for perfect adhesion to the printing

plates and the polyester carriers. The carriers are then fixed to the printing cylinders and must remain stable during

the high-speed printing operations, and must compensate for any plate deformation.

In the direct flexo printing of corrugated board,the adhesive tapes must allow for perfect adhesion to the printing

plates and the polyester carriers. The carriers are then fixed to the printing cylinders and must remain stable during

the high-speed printing operations, and must compensate for any plate deformation.

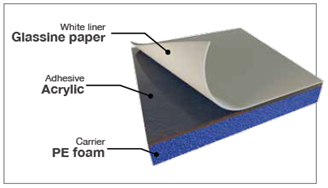

The wide range of BiesSse products includes rigid and soft non-cushioning double-sided adhesives tapes and base

cushioning foams for high process efficiency and high quality post-print.

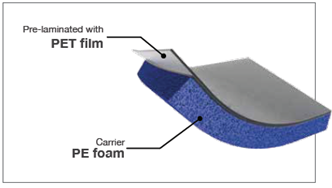

The BiesSse MS FOAM range is mainly used for high-quality flexo post-printing of corrugated board.

The closed-cell polyethylene foam backing offers high resistance and resilience, thus optimizing print process and quality.

It allows for the reduction of the thickness of the printing plates, ensures excellent cushioning and press vibration

absorption even at high printing speed, and avoids cardboard crush reducing dot gain and the “washboard effect”.

The MS FOAM range is available in two versions with different thicknesses: MS FOAM SA (Self-Adhesive) self-adhesive

foam with paper liner, MS FOAM PET with polyester film laminated foam.

| Foam thickness(mm) guaranteed minimum | MS FOAM SA |

| 1.10 | MS FOAM 1100 SA |

| 1.70 | MS FOAM 1700 SA |

| 2.10 | MS FOAM 2100 SA |

| 2.60 | MS FOAM 2600 SA |

| Foam thickness(mm) guaranteed minimum | MS FOAM PET |

| 1.10 | MS FOAM 1100 PET |

| 1.70 | MS FOAM 1700 PET |

| 2.10 | MS FOAM 2100 PET |

| 2.60 | MS FOAM 2600 PET |

Address 63A, HSIIDC, Sector 31, Faridabad 121003

Mobile 9810238588

Email info@printechsystems.in,

dg@printechsystems.in

Copyright 2022. Creatively Crafted by Web Seekers